The logistics automation market is growing rapidly due to increased demand for efficient supply chain solutions. Technological advancements drive this expansion.

Logistics automation involves using technology to enhance and streamline logistics operations. Companies seek automation to reduce manual labor, improve accuracy, and increase efficiency. Key technologies include robotics, AI, IoT, and automated storage and retrieval systems (ASRS). These innovations help businesses manage complex supply chains, reduce costs, and improve customer satisfaction.

The e-commerce boom and global trade expansion further fuel demand for logistics automation. Businesses across various industries invest in automated solutions to stay competitive. As technology evolves, the logistics automation market will likely continue its upward trajectory, offering numerous opportunities for growth.

Introduction To Logistics Automation

Logistics automation is a game-changer in supply chains. It uses technology to streamline operations. This leads to faster deliveries and lower costs. Let’s dive into what it means.

Definition And Scope

Logistics automation involves using software and machinery. These tools handle tasks like inventory management and transportation. It covers various activities:

- Order processing

- Warehouse management

- Transportation planning

- Real-time tracking

Automation makes these processes more efficient. It ensures accuracy and speed. This is crucial for businesses of all sizes.

Importance In Modern Supply Chains

Modern supply chains are complex. They span across continents. Logistics automation helps manage this complexity. It offers several benefits:

- Efficiency: Automation reduces manual tasks. This saves time and resources.

- Accuracy: Automated systems minimize errors. This leads to better customer satisfaction.

- Scalability: Businesses can easily scale operations. Automation supports growth without major changes.

These benefits make logistics automation essential. It helps businesses stay competitive.

Benefit Description Efficiency Reduces manual tasks, saves time and resources Accuracy Minimizes errors, improves customer satisfaction Scalability Supports business growth without major changes

Key Technologies In Logistics Automation

The logistics automation market is evolving with groundbreaking technologies. These innovations streamline operations and enhance efficiency. Key technologies like robotics, AI, IoT, and smart sensors play a crucial role.

Robotics And Ai

Robotics and AI are transforming logistics. Robots handle repetitive tasks with precision. They reduce human error and improve productivity. AI algorithms optimize routes and manage inventory efficiently. Together, they ensure seamless warehouse operations.

Iot And Smart Sensors

IoT and smart sensors bring real-time visibility to logistics. They track shipments and monitor environmental conditions. Smart sensors detect temperature, humidity, and shock. IoT devices relay this data to central systems. This ensures goods are safe and delivered on time.

Below is a table showcasing the benefits of these technologies:

Technology Benefit Robotics Enhances precision and reduces errors AI Optimizes routes and manages inventory IoT Provides real-time tracking Smart Sensors Monitors environmental conditions

These technologies offer numerous advantages:

- Increased efficiency: Automation speeds up processes.

- Cost savings: Reduces labor and operational costs.

- Enhanced accuracy: Minimizes human errors.

- Improved safety: Monitors conditions to prevent damage.

Adopting these technologies is essential for modern logistics. They ensure smooth, efficient, and reliable operations.

Benefits Of Automation In Logistics

Automation in logistics brings many advantages. Businesses can optimize operations and improve customer satisfaction. Automation can drive growth and success in the logistics industry.

Cost Reduction

Automation helps reduce costs in many ways. Automated systems minimize human errors. This results in fewer mistakes and less waste. Companies save money on labor costs. Robots and automated machines work faster than humans. They also work longer hours without breaks.

Automated inventory management systems track stock levels accurately. This reduces the need for excess inventory. Companies spend less on storage and warehousing. Automated systems also streamline shipping and delivery processes. This reduces transportation costs significantly.

Enhanced Efficiency

Automation improves the efficiency of logistics operations. Machines and software perform tasks quicker than humans. This speeds up order processing and fulfillment. Customers receive their orders faster, improving satisfaction.

Automated systems provide real-time data and analytics. This helps managers make informed decisions quickly. They can identify bottlenecks and optimize workflows. Automated sorting and packing systems increase accuracy and speed. This reduces the time taken to prepare orders for shipping.

Benefit Description Cost Reduction Lower labor costs, fewer errors, reduced storage expenses Enhanced Efficiency Faster order processing, real-time data, optimized workflows

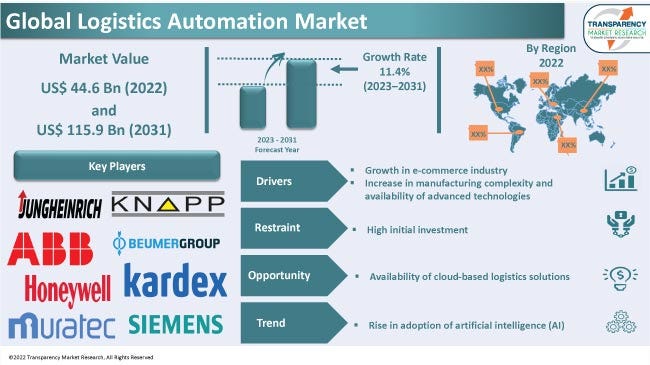

Credit: www.transparencymarketresearch.com

Challenges In Implementing Automation

Logistics automation offers many benefits. But there are challenges too. Companies face hurdles when they decide to automate their logistics processes. Understanding these challenges is important for a smooth transition.

High Initial Investment

The initial cost of automation is high. Companies need to invest in advanced technologies. These include robotics, software, and smart sensors. The infrastructure must also be updated to support these technologies. Small and medium-sized businesses may find this cost prohibitive.

Expense Type Cost Range Robotics $50,000 — $200,000 Software $20,000 — $100,000 Sensors $5,000 — $50,000

Additionally, there are costs for training and maintenance. These add to the overall investment. Planning and budgeting become critical to handle these expenses.

Workforce Adaptation

Another challenge is workforce adaptation. Employees need to learn new skills. They must get comfortable with new technologies. This requires time and training. Resistance to change is common.

- Employees may fear job loss.

- They may be unsure about their new roles.

- Training programs must be effective and engaging.

Proper communication helps ease these fears. Involving employees in the process can also help. This ensures a smoother transition and better acceptance of automation.

Case Studies Of Successful Automation

The logistics automation market is rapidly evolving. Businesses are increasingly adopting automation to enhance efficiency and reduce costs. Let’s explore some successful case studies of automation in logistics.

Amazon’s Automated Warehouses

Amazon leads the way in warehouse automation. Their warehouses are filled with robots and advanced technology.

- Robotic Systems: Thousands of robots assist in moving goods.

- AI and Machine Learning: Algorithms optimize the placement and retrieval of items.

- Automated Sorting: Packages are sorted automatically for faster delivery.

Amazon’s system improves efficiency and reduces human error. This allows them to fulfill orders quickly and accurately.

Ups’s Smart Logistics Network

UPS has developed a smart logistics network using automation and data analytics.

Feature Description ORION System Optimizes delivery routes to save fuel and time. Automated Warehouses Uses robots for sorting and packing. Real-time Tracking Provides live updates on package location.

UPS’s smart logistics network enhances delivery speed and accuracy. It also reduces operational costs and environmental impact.

Future Trends In Logistics Automation

The logistics automation market is evolving rapidly. New technologies are shaping the future. Companies are adopting innovative solutions to streamline operations and boost efficiency. Below, we explore key future trends in logistics automation.

Ai-driven Decision Making

AI-driven decision making is transforming logistics. AI helps optimize routes and reduce delivery times. It analyzes large datasets quickly. This leads to more accurate forecasting.

AI can predict demand spikes. It ensures inventory levels are optimal. Companies can avoid stockouts and overstock situations. AI also helps in warehouse management.

- Automated sorting systems

- Predictive maintenance for equipment

- Efficient resource allocation

AI-driven decision making improves overall efficiency and reduces costs.

Blockchain For Transparency

Blockchain technology ensures transparency in logistics. It provides a secure way to track shipments. Each transaction is recorded on a digital ledger.

This technology offers several benefits:

Benefit Description Enhanced Security Data is encrypted and immutable. Real-time Tracking Shipments can be tracked in real-time. Fraud Prevention Reduces the risk of fraud and errors.

With blockchain, all parties have access to the same information. This reduces disputes and ensures trust.

Impact On Employment

The rise of logistics automation is changing the job market. This innovation affects employment in many ways. Let’s explore the impact on employment.

Job Displacement Concerns

Logistics automation can lead to job losses. Machines and robots replace human workers. This is called job displacement. Many workers worry about losing their jobs. They fear machines will take over their roles.

For example, warehouse workers face job risks. Automated systems can do their tasks. These machines work faster and don’t need breaks. As a result, companies might hire fewer humans.

New Skill Requirements

Automation creates new job opportunities too. Workers need new skills to work with machines. They must learn to operate and maintain these systems. This shift is called upskilling.

Here are some new skills workers need:

- Technical skills to handle machines

- Problem-solving skills to fix issues

- Programming skills to manage software

Companies can help workers learn these skills. They can offer training programs. This helps workers stay employed in the new job market.

Logistics automation changes the job market. It causes job losses and creates new roles. Workers must adapt to these changes to stay relevant.

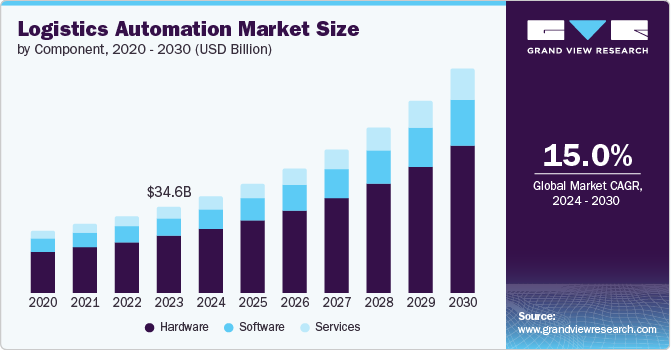

Credit: www.grandviewresearch.com

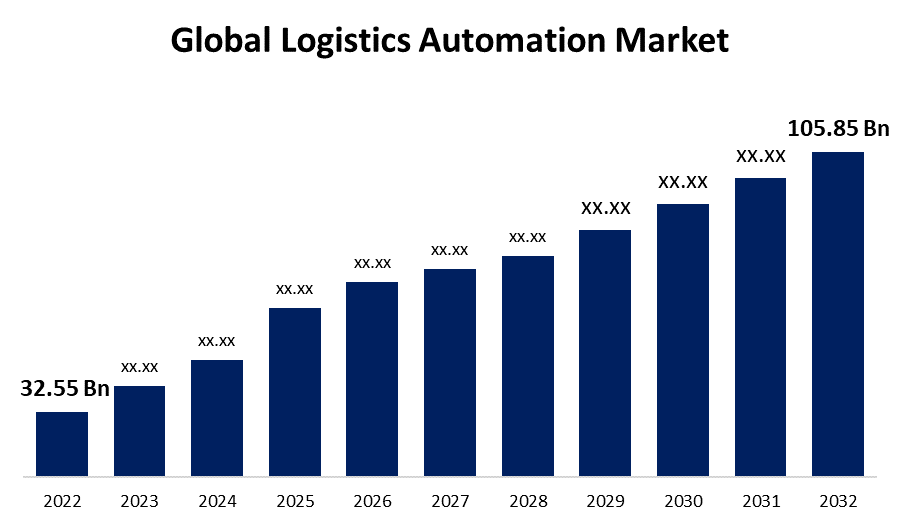

Credit: www.sphericalinsights.com

Frequently Asked Questions

What Is Logistics Automation?

Logistics automation involves using technology to streamline logistics processes. It includes tasks like order processing, inventory management, and transportation. Automation improves efficiency and reduces errors.

Why Is Logistics Automation Important?

Logistics automation increases operational efficiency and accuracy. It reduces manual labor, speeds up processes, and lowers costs. It also enhances customer satisfaction by ensuring timely deliveries.

What Technologies Drive Logistics Automation?

Technologies driving logistics automation include AI, IoT, robotics, and machine learning. These technologies optimize inventory management, improve forecasting, and streamline shipping processes.

How Does Automation Impact Supply Chain Management?

Automation enhances supply chain management by improving accuracy and efficiency. It enables real-time tracking, reduces delays, and minimizes human error. This leads to better decision-making.

Conclusion

The logistics automation market is rapidly evolving. Businesses must adapt to stay competitive. Leveraging automation can streamline operations and reduce costs. Investing in advanced technologies ensures efficient logistics management. Stay ahead by embracing innovations in logistics automation. This will drive growth and improve customer satisfaction.